我国渔业总产量已连续多年居世界首位,其中,淡水鱼的养殖产量占世界2/3以上,2021年我国淡水养殖产量达到3 183.27万t,相比2020年增长了3.06%(农业农村部渔业渔政管理局等, 2022)。白鲢鱼(Hypophthalmichthys molitrix)是我国淡水鱼中资源丰富、产量巨大的鱼类之一,但因其肉薄且骨刺较多、土霉味与鱼腥味较重且不易去除、不宜生鲜食用,并不十分受广大消费者的喜欢。另外,白鲢产量充足、成本低廉,具有低脂肪、高蛋白等优点,是制作鱼糜的经济性选择,目前已被广泛应用于工业化生产鱼糜制品(孙静文, 2016)。鱼糜制品如鱼丸、鱼肠、鱼糕等属于低脂肪、高蛋白的营养健康食品,深受消费者喜爱(唐淑玮等, 2019),且其风味是消费者关心的质量属性之一,而关键气味活性物质的吸附释放规律并不明确。现有对鱼糜气味研究技术十分丰富,主要为仪器分析法(气相色谱–质谱联用、气相色谱–嗅觉测定法、气相色谱–嗅闻–质谱联用、电子鼻技术等)、感官组学分析法(气味活度值、芳香提取物稀释分析、气味重组、气味遗漏实验等)和酶联免疫法(ELISA)等。目前,气味感官实验的研究对象大多为米酒类、油类、蔬果类、菌类等(Xu et al, 2019; Sun et al, 2021; 卢祺, 2022),且现有气味研究主要在配置溶液中进行,主要采用液体模拟体系的气味重组(An et al, 2020; 王国超等, 2012),这与真实的气味活性物质—固态鱼糜之间的相互作用存在一定差异,因此,基于固态鱼糜进行气味研究是十分必要的,可以更好地研究各气味成分与鱼糜无气味本底之间的互作关系。

如何基于固态鱼糜构建气味重组或缺失模型,首先要建立一个无气味或低气味的鱼糜本底模型。淡水鱼气味中有多种复杂成分,主要包括醛类、醇类、酮类、烃类和少量的呋喃类等(王国超等, 2012)。气味物质来源复杂,主要有养殖环境中存在的土臭素(GEO)和二甲基异莰醇(MIB)、酶的催化分解、游离脂肪酸的氧化分解等因素导致(吴燕燕等, 2016)。目前,鱼糜加工过程中减少气味残留的方法主要有物理法(感官掩蔽法、浸泡或漂洗法、吸附法、微胶囊法、包埋法、辐照法、电渗析法)、化学法(酸碱盐法、抗氧化剂法、有机溶剂萃取法、臭氧法)、生物法(酵母菌、乳酸菌、醋酸杆菌发酵)等(柳敏, 2015; 苏怡等, 2019; 杨运懿, 2021),其中,物理法是应用历史最久的方法,化学法在鱼糜制品的生产实践中有广泛的应用,生物法具有去除率高、环境友好、成本低等特点(Yuan et al, 2021)。然而,国内外报道中关于漂洗鱼糜的研究大多是基于如何更好地应用于食品体系,在漂洗试剂的选择上存在一定局限性,对腥味的洗脱能力受限,腥味成分残留仍较多,无法用于构建无腥味或低腥味鱼糜模型。因此,本研究选择盐、盐–醇、酸、碱等漂洗介质,并不限于食品体系,通过比较不同漂洗介质对鱼糜气味的脱除效果,以此构建出无气味或低气味的鱼糜本底模型。

固相微萃取(SPME)具有操作简单、灵敏度高、重现性好的优点,可以获得更真实的分析结果(Ma et al, 2013)。气相色谱–质谱(GC-MS)是分离和鉴定挥发性化合物的常用方法,已广泛应用于挥发性化合物分析(Iglesias et al, 2009)。电子鼻是一种分析、识别和检测简单和复杂气味的仪器。因其测定结果客观、重复性好、不损伤样品及快捷等特点,可以客观地判断不同样品间的挥发性气味是否具有差异性,被广泛地运用于水产品挥发性物质检测,为其气味和品质鉴定提供参考依据(杨欣怡等, 2015; 康翠翠等, 2018; 赵玲等, 2021)。本研究以白鲢鱼糜为研究对象,通过SPME-GC-MS、电子鼻以及感官评价方法研究鱼糜中挥发性风味物质和盐、盐–醇、酸、碱等漂洗介质对气味物质残留率的影响,对于建立无气味或低气味的固体鱼糜模型有一定的学术指导意义。

1 材料与方法 1.1 材料与试剂鲜活白鲢鱼购自江苏省无锡市滨湖区欧尚超市,所选鱼体平均质量为(2.5±0.2) kg/尾,于2021年3月下旬至4月中旬采购;2,4,6-三甲基吡啶标准品(trimethyl pyridine, TMP)购于上海百灵威科技公司;NaCl、无水乙醇、Na2CO3、CaCl2、HCl和NaOH等化学试剂均为分析纯,购于国药集团化学试剂有限公司。

1.2 仪器与设备MDF-U53V型超低温冰箱,日本三洋公司;多功能食品加工机,浙江温州福菱科技有限公司;4K15冷冻离心机,德国Sigma公司;T10 Basic ULTRA-TURRAX均质机,广州IKA仪器设备有限公司;卧式冷藏冷冻转换柜,山东青岛海尔电冰柜有限公司;TSQ 8000型三重四级杆气质联用仪(GC-MS),美国赛默飞世尔科技公司;Heracles II型快速气相色谱电子鼻,法国Alpha MOS S.A.公司。

1.3 实验方法 1.3.1 样品制备新鲜白鲢鱼宰杀后去鳞、去头、去内脏、去除血块和黑色腹膜,然后清洗3~5次,从背部切成两半,去除椎骨,手工剥离鱼刺,以获得白肉。由斩拌机绞碎获得白鲢生鲜鱼糜,用聚乙烯自封袋包装,储存在冰箱(–20 ℃)中备用。

1.3.2 白鲢鱼糜的漂洗方法鱼糜样品在4 ℃下解冻12 h,并用漂洗液处理。实验中所用的不同漂洗介质溶液见表 1。参照Zhou等(2016),漂洗介质A、B、C、D、E和F组的具体漂洗步骤如下:解冻后的鱼肉样品分别取相同质量,每个样品漂洗3次(5倍于鱼肉体积的漂洗液),每次漂洗时间为15 min,漂洗后进行冷冻离心脱水(4 ℃, 4 000 r/min, 4 min),以此得到漂洗鱼糜。

|

|

表 1 不同漂洗介质的组成 Tab.1 The components of different rinsing media |

漂洗介质G组和H组的具体漂洗步骤如下:解冻后的鱼肉样品加入5倍体积的蒸馏水,用均质机缓慢搅拌,同时缓慢滴加几滴1 mol/L HCl或1 mol/L NaOH调整pH,pH分别调到预定值2.3 (G组)和11.8 (H组),再搅拌15 min;然后离心(4 ℃, 10 000 r/min, 20 min),去掉沉淀。调整上清液pH值到5.5,再次离心(4 ℃, 10 000 r/min, 20 min),下层沉淀即为所得漂洗鱼糜。

以上各介质均溶解在蒸馏水中,且它们的使用浓度均经预实验优化过。考虑到乙醇具有很强的挥发性,大量的乙醇在SPME提取时可能会吸附到萃取头,影响其他挥发性成分的吸附。因此,在冲洗的最后步骤,漂洗液与鱼糜通过离心分离,并用清水清洗一次,确保各漂洗介质在鱼糜中无残留。样品封装于铝箔袋中,于–80 ℃超低温冰箱中贮存待测。整个过程均在0~10 ℃下操作。

1.3.3 GC-MS测定挥发性成分的条件固相微萃取法(SPME)条件:样品在提取前按照Gao等(2016)的方法制备,并进行了一些修改。将3.0 g样品放入20 mL的棕色顶空瓶中,加入7 mL饱和NaCl溶液和2,4,6-三甲基吡啶(2,4,6-trimethyl pyridine, TMP, 100 mg/kg),并放入磁力转子,迅速加盖。纤维萃取头(65 μm,PDMS/DVB)插入样品瓶的顶空,在60 ℃吸附30 min后,在250 ℃的注入口解吸3 min。

气相色谱(GC)条件(Gao et al, 2020):使用TG-5毛细管柱(60.00 m × 0.25 mm × 0.25 μm);载气为He,恒定流量1.0 mL/min。升温程序:初始温度40 ℃;初始时间3 min;进样口温度280 ℃;柱温40 ℃,保持2 min,以5 ℃/min升至90 ℃,保持5 min;不分流模式进样。

质谱(MS)条件:使用EI离子源,离子源温度300 ℃,发射电流25 μA;电子能量70 eV;质量扫描范围设定35~350 m/z;接口温度280 ℃;探测器电压1 000 V。

1.3.4 定性和定量分析定性:挥发性化合物根据系统自带的NIST 2008和Willey 7标准图库以及文献报道的色谱数据进行定性匹配,且仅当正反匹配度均大于800 (最大值为1 000)的化合物才予以报道。同时,以C7~C40的正构烷烃作为标准品,利用标准品的保留时间计算出各个样品中化合物的保留指数,和文献中的保留指数进行对比,结合数据库的分析结果,共同对萃取出的挥发性化合物进行定性分析(康翠翠等, 2018)。

定量:将10 μL原始质量分数为100 mg/kg的内标物2,4,6-三甲基吡啶(TMP)加入(3.000±0.006) g鱼糜样品中,通过将各化合物的峰面积与TMP的峰面积进行比较,计算出样品中挥发性化合物的浓度,单位为μg/kg (假定各挥发物的绝对校正因子为1.0)。计算公式如下:

| $ 挥发性组分的质量分数=[(A_{x}×A_{T}^{–1})×m_{T}]×m_{x}^{–1}×10^{3} $ |

式中,Ax、AT分别为挥发性组分x与TMP的峰面积,mT是加入的TMP的质量(μg),mx是被测样品的质量(g)(Gu et al, 2013)。

1.3.5 关键气味化合物的确定为评价白鲢鱼糜气味成分的贡献,利用气味活度值公式:

| $\mathrm{OAV}_x=C_x / \mathrm{OT}_x$ |

式中,OAVx表示各风味物质的气味活度值,Cx表示各化合物的浓度,OTx表示各化合物在水中的检测阈值,其中,OAV≥1的化合物可定义为气味活性化合物(Xu et al, 2021)。

1.3.6 挥发物残留率的计算方法漂洗介质的漂洗效果用残留率R表示。计算公式如下:

| $ R = C_{x}/C_{o} × 100\% $ |

式中,Cx和Co分别为实验组和对照组漂洗后组分x检测出的质量分数(μg/kg) (张建友等, 2015)。

1.3.7 电子鼻分析参考Wen等(2020)的方法并稍加修改,分别准确称取2.0 g前处理好的鱼糜样品置于20 mL顶空瓶中,样品气味比较通过HeraclesⅡ电子鼻进行分析(包含DB-5和DB-1701柱子,10.00 m× 0.25 mm×0.25 μm,Agilent),采用自动顶空进样,每个样品重复3次测定。检测条件如下:在40 ℃下保温30 min,FID检测器温度为250 ℃,氢火焰离子化检测器温度260 ℃;捕集温度50 ℃;阀门温度250 ℃;进样口温度200 ℃;进样量3 000 μL;进样速度125 μL/s。柱温从起始柱温50 ℃以2 ℃/min逐渐升至250 ℃。

1.3.8 感官评价鱼糜样品的感官特性由10名小组成员(2男8女)以5分制进行评估(5分,非常强;4分,强;3分,中等;2分,弱;1分,非常弱)(An et al, 2020)。选取脂肪味、鱼腥味、青草味、泥土味、蘑菇味和金属味6种气味属性作为感官评价指标,来评估样品的强度,结果绘制在雷达图中。所有测试均在室温(22±2) ℃下进行,每个取样一式3份进行。

1.4 数据处理所有实验重复3次,定量结果用“平均值±标准差”(Mean±SD)表示。通过Excel 2019进行数据处理;SPSS 19.0中的Duncan多范围检验评估平均差异方法(P<0.05)进行显著性分析;Origin 2019b进行绘图。

2 结果与讨论 2.1 白鲢生鲜鱼糜挥发性成分鉴定经SPME-GC-MS检测分析,白鲢鱼糜中具体挥发性物质组成及含量如附表1所示。经NIST谱库检索,白鲢鱼糜中共确定65种挥发性物质,其成分主要有醛类(23种)、醇类(13种)、酮类(10种)、烷烃类(7种)和其他类物质(12种),各类物质的相对百分含量分别为37.78%、24.34%、8.83%、2.90%和9.14%,其中,醛类和醇类物质百分含量最高,对鱼糜的气味起主要作用,这与文献中已报道的白鲢鱼糜气味组成成分基本相符(An et al, 2020; Zhou et al, 2016; Geng et al, 2022)。经仪器检测的这些气味物质成分中,醛类中戊醛、己醛、庚醛、辛醛、壬醛含量较高,分别占总含量的1.76%、21.10%、3.22%、2.84%和4.94%;醇类中正戊醇、正己醇、庚醇、1-辛烯-3-醇、辛醇含量较高,分别占总含量的1.31%、6.00%、2.02%、8.31%和3.4%;酮类中2-庚酮、2,5-辛二酮含量较高,分别占总含量的1.10%和5.21%;烃类化合物中3,5,5-三甲基-2-己烯含量较高,占总含量的1.15%;其他化合物中氨基甲酸、2-乙基呋喃、八甲基环四硅氧烷含量较高,分别占总含量的1.92%、1.54%和3.10%,其中,八甲基环四硅氧烷可能是萃取头涂层上的物质脱落而致。有18种物质的气味活度值OAV≥1,如附表1所示,分别是戊醛、己醛、庚醛、辛醛、(E)-2-辛烯醛、壬醛、(E)-2-壬烯醛、癸醛、(E)-2-癸烯醛、十一醛、正己醇、庚醇、1-辛烯-3-醇、辛醇、1-壬醇、2-乙基呋喃、2-戊基呋喃和乙酸乙酯。

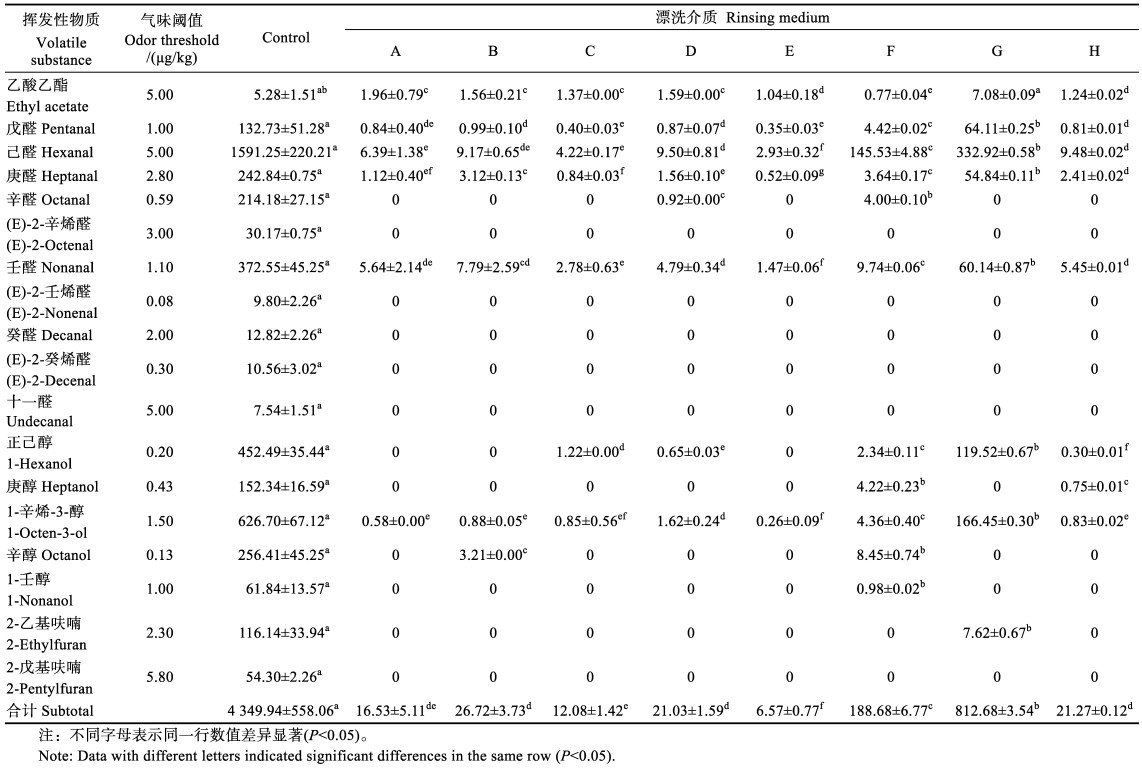

2.2 不同漂洗介质对白鲢鱼糜挥发性物质的影响白鲢鱼糜中气味物质组成复杂,部分气味物质会与蛋白质等大分子物质结合的形式存在(蒋娅婷等, 2014)。采用不同漂洗介质处理,不仅可以通过直接漂洗达到脱脂脱腥的目的,还可以通过破坏气味物质与蛋白等大分子物质之间的结合作用力而达到降低气味残留量的目的(柳敏, 2015)。不同漂洗工艺对白鲢鱼糜挥发性物质的影响如表 2所示。经8种漂洗介质处理后,鱼糜中挥发性物质均有明显减少,样品中分别含有6、8、7、9、6、12、9和9种气味活性物质,挥发性气味物质的残留量依次为16.53±5.11、26.72± 3.73、12.08±1.42、21.03±1.59、6.57±0.77、188.68±6.77、812.68±3.54和(21.27±0.12) μg/kg,其气味残留率分别为(0.380±0.120)%、(0.610±0.086)%、(0.280±0.033)%、(0.480±0.037)%、(0.150±0.018)%、(4.330±0.160)%、(18.680±0.081)%和(0.490±0.003)%,其中,漂洗液A、B、C、D、E和H组这6组漂洗方式对白鲢鱼糜处理后,对醛类物质中的戊醛、己醛、庚醛、辛醛、壬醛和醇类物质中的正己醇、庚醇、1-辛烯-3-醇、辛醇等有明显影响,均大大降低了气味残留率。但漂洗液F组对醛类物质中的己醛气味残留量高达(145.53±4.88) μg/kg,漂洗液G组对醛类物质中的戊醛、己醛、庚醛、壬醛和醇类物质中的正己醇、1-辛烯-3-醇起不到良好的去除作用,原因可能是溶液浓度过高,可能导致部分鱼糜中的蛋白质变性,造成蛋白网络结构的物理阻碍,从而产生更多的挥发性物质。比较8种漂洗介质,发现漂洗液E组对鱼糜气味残留的影响较佳,挥发性物质总含量最低,其中,漂洗后己醛和1-辛烯-3-醇的残留量分别为2.93±0.32和(0.26±0.09) μg/kg,各自的气味残留率仅为0.18%和0.04%。

|

|

表 2 不同漂洗介质处理后气味活性物质的残留量 Tab.2 Residual amount of odour active substances after treatment with different rinsing media(ug/kg) |

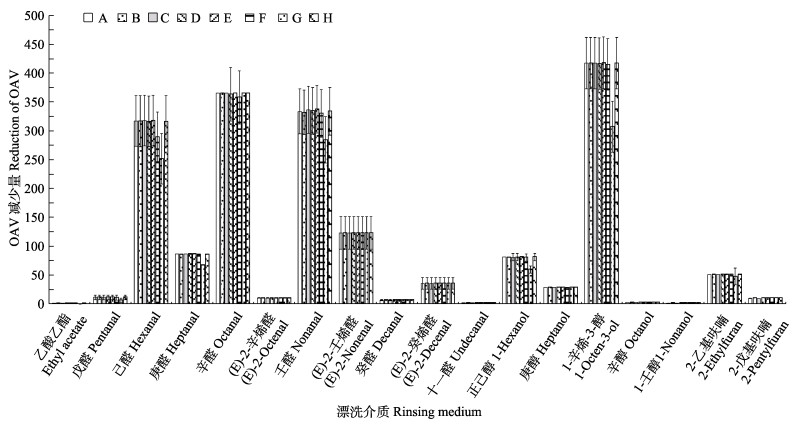

NaCl和Na2CO3是常用的漂洗介质,NaCl和Na2CO3共存的状态下,水产品中气味成分先与Na2CO3发生反应生成无腥味的物质,后者进一步在NaCl的作用下从水产品中析出(柳敏, 2015)。Na+和Ca2+等离子的存在能溶出鱼糜中的血红蛋白,蛋白质损失增加,削弱了与挥发性气味物质的结合能力,进而促使溶液中挥发性物质的释放。Na2CO3可与气味成分反应生成无腥味的物质,也可将容易降解成醛酮类物质的油脂水解成能溶于水的高级脂肪酸钠盐和甘油(游丽君等, 2008),从而达到降低气味残留率的目的。图 1显示了不同漂洗介质对18种气味活性物质OAV减少量的影响。OAV变化可以表明不同的漂洗介质可能会导致样品的整体气味分布发生显著变化(Zhou et al, 2016)。结合表 2和图 1可知,在8组漂洗介质中,18种气味活性物质的OAV总值分别降低为7.66±2.56、11.02±2.62、4.80±0.99、9.93±0.68、2.52±0.25、50.27±1.61、283.22±1.60和8.77±0.04,其中,漂洗液E组对OAV的影响最明显;(E)-2-辛烯醛、(E)-2-壬烯醛、癸醛、(E)-2-癸烯醛、十一醛和2-戊基呋喃等6种气味活性物质均未检出气味残留量,其OAV减少率达到最大;己醛、辛醛、壬醛和1-辛烯-3-醇的OAV下降幅度较大,其OAV减少量均在200以上。综上所述,漂洗液E组在加入4.0%乙醇(V/W)溶液后,有17种气味活性物质的OAV<1,仅壬醛的OAV为1.34±0.05,这对降低鱼糜气味残留起到了很好的协同增效作用。乙醇的加入,由于相似相容原理,有利于鱼糜脂质的酯化,加快了气味成分的溶出;同时使鱼糜表面脱水,通过溶质浓缩效应造成蛋白质变性,从而破坏挥发性气味物质与蛋白质等大分子物质之间的结合作用力,而高浓度的NaCl加速蛋白变性,促进溶液中挥发性物质的释放,大大降低了气味物质中醛类和醇类的残留率,从而可构建出低气味的鱼糜本底模型。

|

图 1 不同漂洗介质对气味活性物质OAV的影响 Fig.1 Effects of different rinsing media on OAV of odor active substances A、B、C、D、E、F、G和H依次为漂洗介质A、B、C、D、E、F、G和H处理后的鱼糜样品。下同。 A, B, C, D, E, F, G and H were the surimi samples treated with rinsing medium A, B, C, D, E, F, G and H, respectively. The same below. |

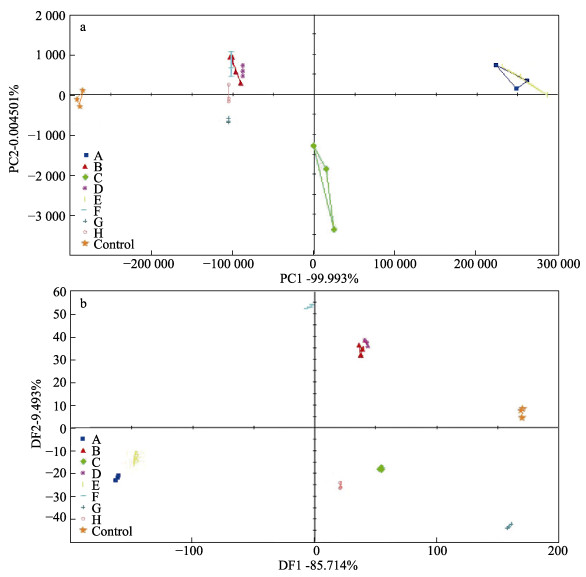

主成分分析法(principal component analysis, PCA)是将传感器提取的原多维矩阵数列通过降维、数据处理和线性分类转换为互不相关的几个综合指标的方法(郑舒文等, 2019)。PCA作为一种常用的降维分析方法,能够将不同样品按照主成分划分在不同的区域,区域之间的距离表示不同样品之间的差异(吴丹等, 2022)。电子鼻响应数据的PCA分析结果如图 2a所示。PCA图由2个轴PC1和PC2组成,其中,PC1的方差贡献率为99.993 0%,PC2的方差贡献率为0.004 5%,2组总贡献率为99.997 5%,表明PC1和PC2 2个主要成分可以代表几种被测试样品的整体气味特征。从图 2a中可以看出,A组和E组样品与新鲜鱼糜样品在PC1的距离远大于其他样品,在气味上有部分相似,表明漂洗介质A组和E组的漂洗效果更为明显。判别因子分析法(discriminant factor analysis, DFA)是用少数几个因子来描述多个因素之间的联系与差异,通过DFA分析可以使样品组间距离最大的同时保证组内差异最小,进行定性判别,对样品间的差异较PCA有更好的区分度(吴丹等, 2022)。根据DFA分析结果,DF1和DF2方差贡献率分别为85.714%和9.493%。95.207%的总体方差贡献率,表明DFA分析能有效区别各组样品的气味差异。根据图 2b可知,A组和E组与新鲜鱼糜样品距离较远。电子鼻分析结果与GC-MS分析结果基本一致,进一步证实A组和E组的漂洗处理都能有效降低鱼糜的气味残留量。

|

图 2 不同鱼糜样本电子鼻响应数据的PCA(a)和DFA(b) Fig.2 PCA (a) and DFA (b) of e-nose response data for different surimi samples Control:新鲜鱼糜。下同。 Control: Fresh surimi. The same below. |

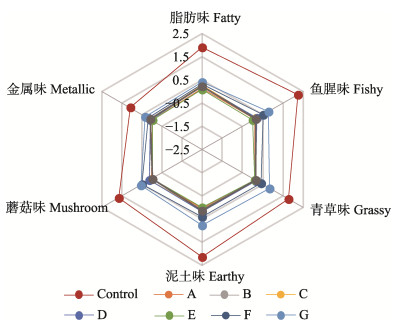

不同鱼糜样品漂洗前后的气味感官雷达图如图 3所示。与新鲜白鲢鱼糜样品的感官评分相比,8种漂洗介质处理后的样品都影响了鱼糜的气味感官轮廓,在一定程度上都降低了各个气味属性的评分,尤其是漂洗介质A、B、C、D和E组漂洗处理后,对“鱼腥味”、“脂肪味”、“泥土味”、“青草味”、“蘑菇味”和“金属味”等6种气味属性均有显著影响,这与GC-MS和电子鼻的分析结果基本一致。然而,该感官评价实验并不能够很好地区分漂洗后的不同鱼糜样品,尤其是对于A、B、C、D和E组漂洗介质,它们各气味属性得到的感官评分值基本在同一水平位置,在雷达图(图 3)中的感官轮廓很难区分开来。其中,E组漂洗处理后对各气味属性的影响较为明显,6种气味属性的感官评分值基本为0,说明漂洗后的样品已经达到了低气味的水平,符合低气味固体鱼糜模型的构建标准。

|

图 3 不同鱼糜样品的气味感官雷达图 Fig.3 Odor sensory radar chart of different surimi samples |

经SPME-GC-MS分析,在白鲢鱼糜中共检出65种挥发性物质,主要包括醛类22种、醇类13种、酮类9种及烃类7种等,其中,醛类和醇类物质含量较高,对白鲢鱼糜的气味有主要的贡献作用。采用气味活度值法(OAV≥1),共鉴定出18种气味活性物质,这有助于说明气味活性物质贡献了鱼糜整体气味。由GC-MS分析结果可知,8种漂洗介质在不同程度上洗去或释放了白鲢鱼糜中气味活性物质的残留量,从而影响了样品的整体气味贡献。相较于其他漂洗介质,漂洗介质E组由于乙醇的协同作用,检出的挥发性物质最少,气味活性物质的总残留量为(6.57±0.77) μg/kg,总残留率仅为0.154%,OAV总值降低至2.52±0.25,对气味物质的去除效果最佳。同时,电子鼻检测和感官评价也区分了不同漂洗样品和新鲜鱼糜之间的整体气味特征差异。该研究对于建立低气味的固体鱼糜模型有一定的学术指导意义,为感官组学分析提供了一种新思路。

附录|

|

表 附表1 白鲢鱼糜的挥发性成分物质组成及含量 Tab.附表1 Composition and content of volatile components in silver carp surimi |

AN Y Q, QIAN Y P, MAGANA A A, et al. Comparative characterization of aroma compounds in silver carp (Hypophthalmichthys molitrix), Pacific whiting (Merluccius productus), and Alaska pollock (Theragra chalcogramma) surimi by aroma extract dilution analysis, odour activity value, and aroma recombination studies. Journal of Agricultural and Food Chemistry, 2020, 68: 10403-10413 DOI:10.1021/acs.jafc.9b07621 |

Bureau of Fisheries, Ministry of Agriculture and Rural Affairs, National Fisheries Technology Extension Center, China Society of Fisheries. China fishery statistical yearbook 2022. Beijing: China Agriculture Press, 2022 [农业农村部渔业渔政管理局, 全国水产技术推广总站, 中国水产学会. 2022中国渔业统计年鉴. 北京: 中国农业出版社, 2022]

|

GAO P, JIANG Q X, XU Y S, et al. Aroma profiles of commercial Chinese traditional fermented fish (Suan yu) in Western Hunan: GC-MS, odour activity value and sensory evaluation by partial least squares regression. International Journal of Food Properties, 2020, 23(1): 213-226 DOI:10.1080/10942912.2020.1716790 |

GAO P, WANG W X, JIANG Q X, et al. Effect of autochthonous starter cultures on the volatile flavour compounds of Chinese traditional fermented fish (Suan yu). International Journal of Food Science and Technology, 2016, 51(7): 1630-1637 DOI:10.1111/ijfs.13134 |

GENG H Y, CHEN L H, WANG S F, et al. Analysis of volatile compounds contributing to distinctive odour of silver carp (Hypophthalmichthys molitrix) surimi. International Journal of Food Science and Technology, 2022, 57: 7774-7786 DOI:10.1111/ijfs.16141 |

GU S Q, WANG X C, TAO N N, et al. Characterization of volation of volatile compounds in different edible parts of steamed Chinese mitten crab (Eriocheir sinensis). Food Research International, 2013, 54(4): 81-92 |

IGLESIAS J, MEDINA I, BIANCHI F, et al. Study of the volatile compounds useful for the characterisation of fresh and frozen-thawed cultured gilthead sea bream fish by solid- phase microextraction gas chromatography-mass spectrometry. Food Chemistry, 2009, 115(4): 1473-1478 DOI:10.1016/j.foodchem.2009.01.076 |

JIANG Y T, CAO J X, ZHANG Y L, et al. A proceeding of research in the interactions of protein with volatile flavor compounds. Journal of Nuclear Agricultural Sciences, 2014, 28(02): 285-291 [蒋娅婷, 曹锦轩, 张玉林, 等. 蛋白质与挥发性风味成分相互作用研究进展. 核农学报, 2014, 28(02): 285-291] |

KANG C C, SHI W Z, FANG L, et al. Effects of different freezing methods on the volatile components of grass carp meat. Food Science, 2018, 39(14): 229-235 [康翠翠, 施文正, 方林, 等. 不同冻结方式对草鱼肉挥发性成分的影响. 食品科学, 2018, 39(14): 229-235 DOI:10.7506/spkx1002-6630-201814034] |

LIU M. Study on the volatile compounds and their combination to proteins of silver carp. Master′s Thesis of Zhejiang University of Technology, 2015 [柳敏. 白鲢鱼肉挥发性风味物质分析及其与蛋白质结合研究. 浙江工业大学硕士研究生学位论文, 2015]

|

LU Q. Identification of American silver carp and characterization of key odor compounds. Master′s Thesis of Shanghai Ocean University, 2020 [卢祺. 冷冻美国鲢鱼气味识别及其特征性关键气味物质研究. 上海海洋大学硕士研究生学位论文, 2020]

|

MA Q L, HAMID N, BEKHIT A E D, et al. Optimization of headspace solid phase microextraction (HS-SPME) for gas chromatography mass (GC-MS) analysis of aroma compounds in cooked beef using response surface methodology. Microchemical Journal, 2013, 111: 16-24 DOI:10.1016/j.microc.2012.10.007 |

SU Y, JIANG Q X, XIA W S. Comparison of effects of different deodorization methods on deodorizing sturgeon fish (Acipenser sinensis). Food Science and Technology, 2019, 44(10): 138-146 [苏怡, 姜启兴, 夏文水. 不同脱腥方法对鲟鱼肉脱腥效果的比较研究. 食品科技, 2019, 44(10): 138-146] |

SUN J W. Effects of washing on proteins and gel properties of grass carp and silver carp surimi. Master′s Thesis of Huazhong Agricultural University, 2016 [孙静文. 不同漂洗对草鱼和白鲢鱼糜蛋白及其凝胶性能的影响. 华中农业大学硕士研究生学位论文, 2016]

|

SUN X Z, DU J W, XIONG Y Q, et al. Characterization of the key aroma compounds in Chinese JingJiu by quantitative measurements, aroma recombination, and omission experiment. Food Chemistry, 2021, 352: 129450 DOI:10.1016/j.foodchem.2021.129450 |

TANG S W, GAO R C, ZHAO Y H, et al. Optimization of rinsing process for sturgeon surimi and its effect on the quality of productions. Progress in Fishery Sciences, 2019, 40(1): 155-160 [唐淑玮, 高瑞昌, 赵元晖, 等. 鲟鱼鱼糜漂洗工艺优化及其对品质的影响. 渔业科学进展, 2019, 40(1): 155-160] |

WANG G C, LI L H, HAO S X, et al. Research progress in the mechanism of odor compounds in aquatic product and some relative techniques of detection and analysis. Food Industry Technology, 2012, 33(5): 401-404 [王国超, 李来好, 郝淑贤, 等. 水产品腥味物质形成机制及相关检测分析技术的研究进展. 食品工业科技, 2012, 33(5): 401-404] |

WEN X Y, CHEN A H, XU Y S, et al. Comparative evaluation of volatile profiles of Asian hard clams (Meretrix meretrix) with different shell colors by electronic nose and GC-MS. Journal of Aquatic Food Product Technology, 2020, 30(1): 1-15 |

WU D, ZENG W H, XIONG S B, et al. Analysis of the deodorization effect of barley green powder on silver carp surimi products by SPME and SDE. Modern Food Science and Technology, 2022, 38(3): 244-256 [吴丹, 曾文浩, 熊善柏, 等. 基于固相微萃取(SPME)和同时蒸馏萃取(SDE)分析大麦苗粉对白鲢鱼糜制品的去腥作用. 现代食品科技, 2022, 38(3): 244-256] |

WU Y Y, ZHU X J. Progress on the source of fishiness materials and their control methods. Chinese Fishery Quality and Standards, 2016, 6(2): 14-19 [吴燕燕, 朱小静. 鱼肉腥味物质的来源及控制方法研究进展. 中国渔业质量与标准, 2016, 6(2): 14-19] |

XU X D, XU R, JIA Q, et al. Identification of dihydro-β-ionone as a key aroma compound in addition to C8 ketones and alcohols in Volvariella volvacea mushroom. Food Chemistry, 2019, 293: 333-339 |

XU Y S, YANG Y Y, LIU C K, et al. Modification of volatile profiles of silver carp surimi gel by immersion treatment with hydrogen peroxide (H2O2). International Journal of Food Science and Technology, 2021, 56: 5726-5737 |

YANG X Y, LIU Y, XU C H, et al. Extraction and analysis of volatile flavor compounds in aquatic products: A review. Food Science, 2015, 36(5): 289-295 [杨欣怡, 刘源, 许长华, 等. 水产品中挥发性风味物质提取和分析研究进展. 食品科学, 2015, 36(5): 289-295] |

YANG Y Y. Effect of hydrogen peroxide moderate oxidation treatment on fishy off-odor deodorization and quality of surimi gel. Master′s Thesis of Jiangnan University, 2021 [杨运懿. 双氧水适度氧化处理对鱼糜凝胶腥味脱除及品质特性的影响. 江南大学硕士研究生学位论文, 2021]

|

YOU L J, ZHAO M M. Advances on the formation and deodorization of fishy odor for fish products. Food and Fermentation Industry, 2008, 34(2): 117-120 [游丽君, 赵谋明. 鱼肉制品腥味物质形成及脱除的研究进展. 食品与发酵工业, 2008, 34(2): 117-120] |

YUAN S, LIU H, LIU M. Application status and prospects of biological deodourization in China. IOP Conference Series: Earth and Environmental Science, 2021, 631(1): 9-12 |

ZHANG J Y, LIU M, GU S Q, et al. Comparative studies on volatile substances of silver carp by different rinsing mediums. Journal of Nuclear Agricultural Sciences, 2015, 29(10): 1954-1962 [张建友, 柳敏, 顾赛麒, 等. 不同漂洗介质对白鲢鱼肉挥发性物质的影响. 核农学报, 2015, 29(10): 1954-1962] |

ZHAO L, CAO R, WANG L Z, et al. Study on the characteristic flavor change of Porphyra yezoensis before and after roasting. Progress in Fishery Sciences, 2021, 42(4): 199-207 [赵玲, 曹荣, 王联珠, 等. 条斑紫菜烤制前后特征风味变化研究. 渔业科学进展, 2021, 42(4): 199-207] |

ZHENG S W, CHEN W H. Evaluation of cod freshness based on electronic nose and electronic tongue technology. Chinese Condiment, 2019, 44(5): 164-169 [郑舒文, 陈卫华. 基于电子鼻和电子舌技术的鳕鱼鲜度评定. 中国调味品, 2019, 44(5): 164-169] |

ZHOU X X, CHONG Y Q, DING Y T, et al. Determination of the effects of different washing processes on aroma characteristics in silver carp mince by MMSE-GC-MS, e-nose and sensory evaluation. Food Chemistry, 2016, 207: 205-213 |