2. 天津市水产生态及养殖重点实验室 天津 300392

2. Tianjin Key Laboratory of Aquatic Ecology and Aquaculture, Tianjin 300392, China

为满足人民群众日益增长的动物性食物消费需求,我国提出建设“蓝色粮仓”的战略。循环水养殖系统(recirculating aquaculture systems, RAS)契合“蓝色粮仓”战略,在有效降低水污染的同时保障了粮食安全(王峰等, 2013; 隋金柱等, 2022; 乔玮等, 2014)。

循环水养殖中,养殖池内的流速对养殖生物有较大影响,圆形养殖池中流速过低时,水体混合效果较差,影响养殖安全;同时,流速过高会直接伤害养殖生物,且会致使循环水系统的后续水处理压力过大。

水产养殖中饲料成本占总生产成本的30%~70% (de Verdal et al, 2018),残饵和排泄物的堆积会产生大量氨氮和亚硝酸盐(吕妍等, 2021; Yusoff et al, 2011),超过一定浓度后对养殖生物有致命性(Xu et al, 2021; 方成等, 2022)。同时,水温也是影响水产养殖生物健康的重要因素(田相利等, 2010; 郭黎等, 2012; 杨凯等, 2020)。因此,研究不同流速对排污和水温的影响,并确定不同生产阶段的进水流速是必要的。

传统的循环水养殖进水流速调控方案通过研究不同流速对养殖品种生长、摄食和水质氮素等的影响,进而确定养殖的适宜流速和经济流速(孙国祥等, 2011),或通过对比不同流速下摄食后12 h内氨氮和亚硝酸盐的质量浓度变化,提出摄食后4~8 h是氨氮和亚硝酸盐生成的高峰期,提高流速可以加快氨氮和亚硝酸盐的排出,其他时间保持较低流速构成的一套变速流方案(沈加正等, 2016)。实际应用中,上述方法通过检测氨氮和亚硝酸盐的方式确定进水流速调控的方法成本高、反馈迟,只能在水质已经变差的情况下调节,无法提前预防水质变差。

计算流体力学(computational fluid dynamics, CFD)采用数值方法利用计算机求解关于流体流动的控制偏微分方程组,并通过计算所得流场来研究流体流动状态与其相关变化。本研究基于Fluent流体仿真软件对不同进水流速下,养殖池流速区大小变化、颗粒物排除效率、水温调节速度进行模拟实验,提出了一种养殖池进水流速调控的实验方法。

1 数值模型建立与验证水产养殖中可使用数值模拟方法解决实际生产中不同流速下的控温效果、固体颗粒物排放效率、流速区划分情况无法直接测量的问题。目前,针对水产养殖多相流数值模拟的研究成果并不多,已有研究集中在养殖池进出水结构和养殖池形状对流场和集排污效果的影响(薛博茹等, 2021; Liu et al, 2023; 胡佳俊等, 2021; 张倩等, 2022),采用数值模拟方法设计进水流速调控方案的研究少有报道。

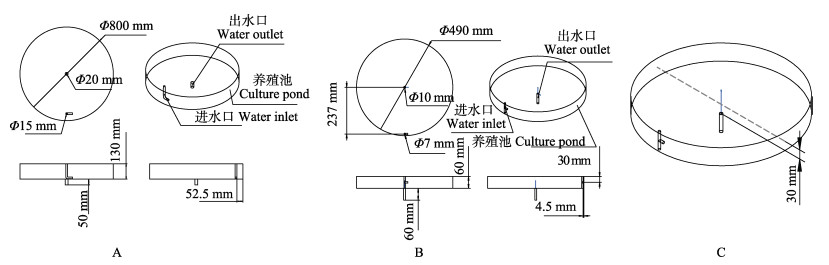

1.1 数值模型建立本研究利用SolidWorks 2018软件,参照实际养殖池尺寸,等比例缩小1/8构建简化圆形养殖池,进行数值模拟。模型各部分如图 1A所示。养殖池半径为40 cm,水深为13 cm。进水管从距壁面52.5 mm处养殖池顶部垂直插入,底部沿养殖池池壁切向进水,管径为DN15。出水口位于养殖池底部正中央,管径为DN20。模型构建后,使用Space Claim软件将流体域划分为主流体域、进水流体域和出水流体域,设置边界名称,并对几何模型进行缝隙检测。

|

图 1 几何模型图 Fig.1 Geometric model diagram A:圆形养殖池模型图;B:验证养殖池模型图;C:检测点示意图。Φ表示所标示圆的内径大小。 A: Model of a circular aquaculture pond; B: Validation of aquaculture pool model; C: Schematic diagram of detection points. Φ indicates the inner diameter size of the marked circle. |

选择使用OCA等(2013)和Duarte等(2011)研究中的圆形养殖池模型,如图 1B所示。其中,湍流模型和壁面函数验证中的检测位置为过养殖池中心平行于进水口的纵切面上距池底0.03 m处的线,如图 1C所示。进行数值模拟结果对比,确定湍流模型和壁面函数。在本研究讨论的模型(图 1A)基础上,确定了DPM多相流模型并进行网格无关性验证。

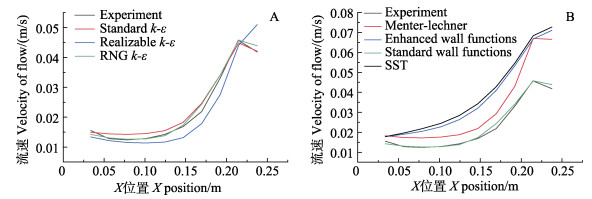

1.2.1 湍流模型参考Ansys理论指南,养殖池内的流场经计算属于高雷诺数,并在充分考虑计算成本的前提下,选择k-ε系列的湍流模型,其中k和ε由式(1)和(2)给出。Standard k-ε模型局限性强,适用于高雷诺数的流场模拟;RNG k-ε相较于标准k-ε模型在ε方程上增加了1项[由式(3)给出],同时增加了涡流对流场的影响;Realizable k-ε模型适用于流动分离和二次流等流场模拟,在射流曲率变化大的情况下有更好的表现。本研究通过实验对比k-ε的3种湍流模型,实验结果如图 2A所示。由图 2A可知,RNG k-ε模型与实验结果拟合度最高,适用于本研究圆形养殖池流场仿真。

| $ \begin{gathered} \frac{\partial }{{\partial t}}(\rho k) + \frac{\partial }{{\partial {x_i}}}(\rho k{u_i}) = \frac{\partial }{{\partial {x_j}}}\left({{\alpha _k}{\mu _{eff}}\frac{{\partial k}}{{\partial {x_j}}}} \right) + \hfill \\ \;\;\;\;{G_k} + {G_b} - \rho \varepsilon - {Y_M} + {S_k} \hfill \\ \end{gathered} $ | (1) |

| $ \begin{gathered} \frac{\partial }{{\partial t}}(\rho \varepsilon) + \frac{\partial }{{\partial {x_i}}}(\rho \varepsilon {u_i}) = \frac{\partial }{{\partial {x_j}}}\left({{\alpha _\varepsilon }{\mu _{eff}}\frac{{\partial \varepsilon }}{{\partial {x_j}}}} \right) + \hfill \\ \;\;\;\;{C_{1\varepsilon }}\frac{\varepsilon }{k}({G_k} + {C_{3\varepsilon }}{G_b}) - {C_{2\varepsilon }}\rho \frac{{{\varepsilon ^2}}}{k} - {R_\varepsilon } + {S_\varepsilon } \hfill \\ \end{gathered} $ | (2) |

| $ {R_\varepsilon } = \frac{{{C_\mu }\rho {\eta ^3}\left({1 - \frac{\eta }{{{\eta _0}}}} \right)}}{{1 + \beta {\eta ^3}}}\frac{{{\varepsilon ^2}}}{k} $ | (3) |

|

图 2 湍流模型仿真效果对比(A)和壁面函数仿真效果对比(B) Fig.2 Comparison of turbulence model simulation effects (A) and wall function simulation effects (B) |

式中,t为时间(s);

标准壁面函数(standard wall functions)是一种壁面函数的方法,用于高雷诺数流动,不适合大压力梯度,一般要求30<Y+<300;增强壁面函数(enhanced wall functions)是一种近壁面模型方法,用于无法应用对数律求解的复杂流动问题,比如边界层分离现象,一般要求Y+≈1;Menter-Lechner处理也是一种近壁面模型方法,该方法在壁面网格足够细时使用一个新低雷诺数模型方法,当壁面函数较粗时,使用壁面函数方法,对Y+无要求。本研究对比了3种壁面函数,结果如图 2B所示。从图 2B可以看出,选择标准壁面函数的模拟结果与实验数据之间的相对误差平均值小于实际生产中的测量误差。因此,本研究的后续实验中均采用RNG k-ε模型和标准壁面函数的配置,稳态求解使用Coupled算法,瞬态求解使用SIMPLE算法。

1.2.3 多相流模型多相流仿真中,离散相模型选择与固体颗粒物的体积分数相关。离散相模型分为拉格朗日法(DPM模型)和欧拉法,其中拉格朗日法忽略了颗粒之间的相互作用,因此,要求固体颗粒物体积分数小于10%~12%,若颗粒体积分数过高则只能采用欧拉法。本研究设计的固体颗粒物体积分数远小于10%,因此,本研究的多相流模型采用DPM模型,式(4)为DPM模型的颗粒受力解析。在本研究中,离散相注入方式选择cone,入射区域设置为与养殖池中心同心、半径为0.35 m的顶部圆形区域。从入射区域随机注入300个半径为0.002 m、密度为1 250 kg/m2的颗粒,并采用离散随机轨迹模型模拟湍流对颗粒物的影响。

| $ {m_p}\frac{{d{{\vec u}_p}}}{{dt}} = {m_p}\frac{{\vec u - {{\vec u}_p}}}{{{\tau _r}}} + {m_p}\frac{{\vec g({\rho _p} - \rho)}}{{{\rho _p}}} + \vec F $ | (4) |

式中,

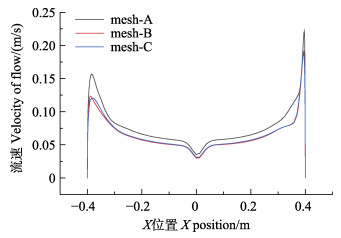

在其他设置完全一致的前提下,本研究比较了不同网格数量时过养殖池中心纵切面上距池底0.065 m处线上的流速大小,结果如图 3所示。其中,mesh-A、mesh-B和mesh-C的网格数量分别为104 662、272 453和1043 274。mesh-B可以用较低的计算成本保证较高的准确性,故选用mesh-B的网格划分方案进行数值模拟。

|

图 3 网格无关性验证 Fig.3 Grid independence verification |

Mesh-B具体的网格划分方案如下:在Fluent Meshing参照表 1的设置划分非结构化网格,其中养殖池主体部分采用六面体网格,进出水口等部分采用多面体网格并对网格进行加密,划分情况如图 4所示。

|

|

表 1 网格划分设置 Tab.1 Grid division settings |

|

图 4 养殖池的网格划分 Fig.4 Grid division of aquaculture ponds |

以大菱鲆(Scophthalmus maximus)为例讨论进水流速对养殖池流场、颗粒物排出效率和水温调节的影响。

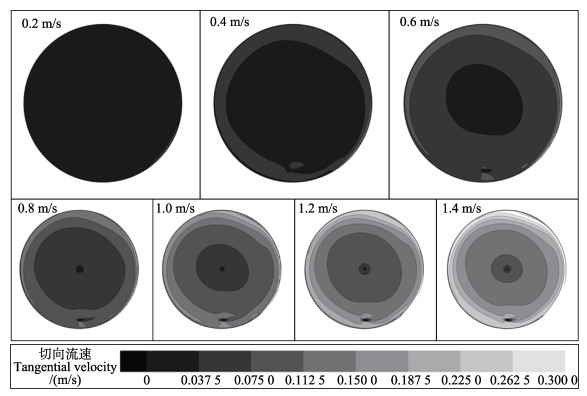

2.1 进水流速对养殖池流场的影响大菱鲆除摄食外,伏底栖息,集群生活(Lei et al, 2005)。因此,本研究选取近池底的水平截面进行流场分析。在不同进水流速下,比较距池底0.01 m处水平截面的切向流速大小,观察流场均匀性,结果见图 5。由图 5可以看出,在一定程度内随进水流速的增大,切向流速增大,整体流场趋于稳定。

|

图 5 水平截面流速变化 Fig.5 Changes in horizontal cross section velocity |

在养殖池流速区的研究中,通常采用2种方案定义流速区:一种是凭经验将低流速标准线定义为固定值(Sin et al, 2021);另一种是将流速和养殖池内平均流速做比值,以比值的大小来定义高、中、低流速区(任效忠等, 2021)。养殖生产中,适宜的流速可以有效增加养殖生物的食用价值并促进养殖生物的生长(Huang et al, 2021),长时间过低的流速会导致养殖生物的肉质营养和水体交换速度降低,过高的流速会对养殖生物的生长和营养成分造成负面影响(钟金鑫等, 2013; Jones et al, 1974; Liao et al, 2007; Zhang et al, 2022; Li et al, 2019)。本研究结合以上研究,提出针对不同养殖生物的适宜流速范围确定流速区划分阈值的划分方法。

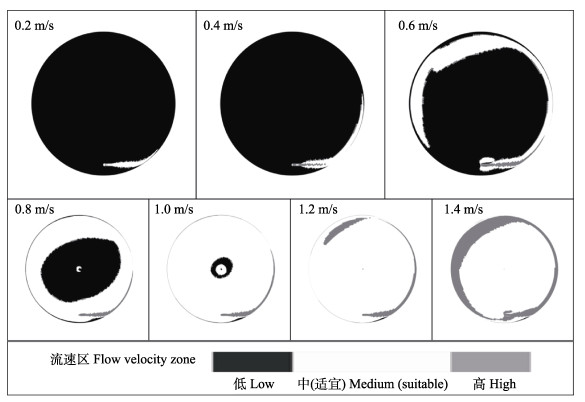

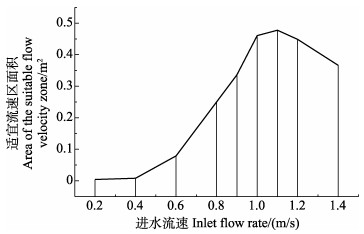

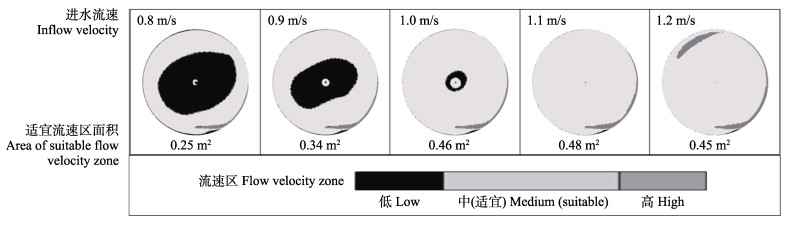

研究表明,平均体长(BL)为22 cm的大菱鲆,流速在0.33~0.46 BL/s时分布更均匀,在流速超过0.98 BL/s时无法正常活动(Almansa et al, 2012)。本研究以大菱鲆为对象,做出如下规定:最低适宜流速0.072 6 m/s (0.33 BL/s)为低流速标准线,流速小于该值的区域定义为低流速区;最高极限流速0.215 6 m/s (0.98 BL/s)为高流速标准线,流速大于该值的区域定义为高流速区;流速介于低流速与高流速之间的区域定义为适宜流速区。不同进水流速依照此规定划分3种流速区分布,结果见图 6。由图 6可以看出,在进水流速为0.2~0.6 m/s时,中、低流速区占比最大;为1 m/s左右时,适宜流速区最大;>1.2 m/s时,高流速区占比增大,适宜流速区减小。为确定适宜进水流速,增加进水流速为1.1 m/s和0.9 m/s下的数值模拟,适宜流速区面积变化见图 7。由图 7可以看出,随进水流速的增大适宜流速区面积先增大后减小,在进水流速为1.1 m/s时,适宜流速区面积达到峰值。

|

图 6 水平截面流速区划分 Fig.6 Division of horizontal cross section velocity zone |

|

图 7 适宜流速区面积变化 Fig.7 Changes in the area of the suitable flow velocity zone |

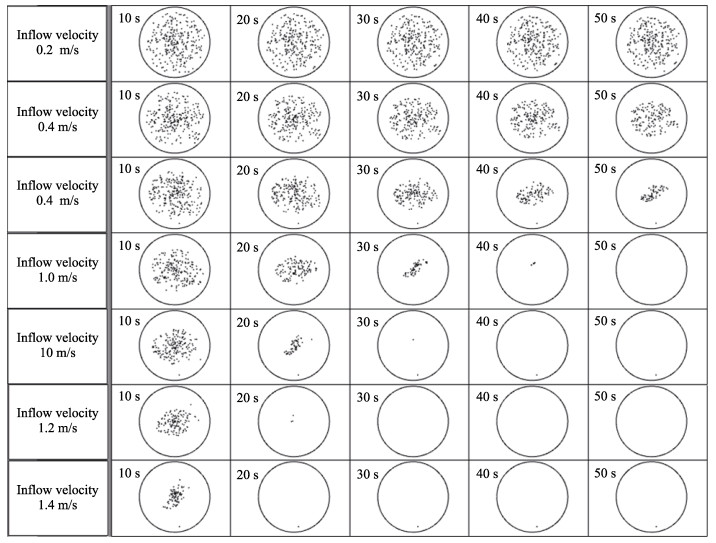

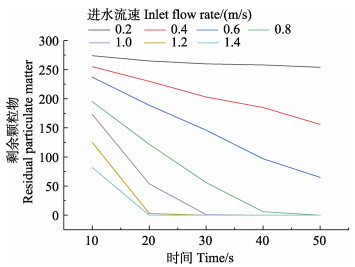

饵料的粒径与养殖品种和养殖周期、养殖环境等有关。以0.002 m的饵料粒径为例,模拟颗粒物在不同进水流速下的颗粒排出效率,结果见图 8、9。由图 8、9可以看出,随进水流速的增大养殖池内颗粒物排出速度加快,且前期排放速度快,后期排放速度减慢。

|

图 8 随着时间变化的颗粒物留存情况 Fig.8 Retention of particulate matter over time |

|

图 9 随着时间变化的颗粒物留存量 Fig.9 Particle retention over time |

将养殖池划分为4个区域,半径<0.1 m的圆形区域为出流区,半径在0.1~0.2 m之间的环形区为次出流区,半径在0.2~0.3 m之间为近壁面区,半径>0.3 m为壁面区,研究不同进水流速下颗粒物分布情况。各区域颗粒物分布情况见表 2。随流速增加,颗粒物聚集位置更趋近于出水口附近,排出效率也显著增加。

|

|

表 2 颗粒物分布情况 Tab.2 Particle distribution |

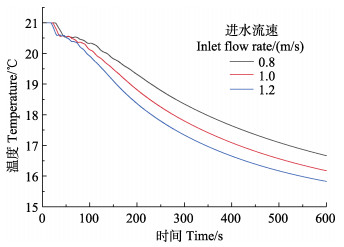

大菱鲆的最适水温为16~18 ℃(李勇等, 2011),本研究将入水温度设置为15 ℃,原池中水温假设为21 ℃开始注水,选择对0.8~1.2 m/s的进水流速进行仿真,在不同进水流速下比较了大菱鲆主要活动区域(距池底0.01 m处水平截面)的平均温度,结果见图 10。由图 10可以看出,在100 s内随进水流速增大调温速度并未有明显变化,在100~350 s内调温效果明显且进水流速越大调温效果越好,在350 s后水温逐渐趋于稳定且调温速度明显减慢。

|

图 10 不同进水流速下养殖池平均水温随时间的变化 Fig.10 Changes of average water temperature of aquaculture ponds over time under different inflow velocities |

由流场仿真结果可以看出,在不考虑进水成本的前提下,进水流速为1.1 m/s时的适宜流速区最大、养殖效果最好。

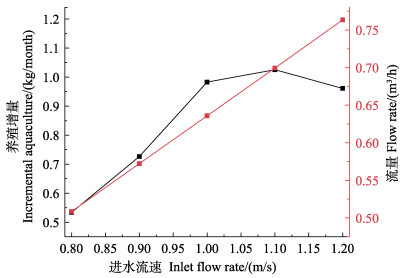

研究显示,大菱鲆最佳养殖密度为8.96 kg/m2,在最佳养殖密度条件下,每月平均增重2.136 4 kg/m2 (王峰等, 2015)。因此,本研究对比了0.8~1.2 m/s时的适宜养殖面积(见图 11)。由图 11可知,进水流速为1.2 m/s时,适宜养殖面积减少、流量增大,流量越大养殖成本越高,因此,1.2 m/s在所讨论的进水流速中经济性最低。进水流速从0.8~1.2 m/s的养殖增量分别为0.534、0.726、0.983、1.025和0.961 kg/月。DN15的进水管道,在0.8~1.2 m/s的进水流速条件下,流量分别为0.508、0.572、0.636、0.699和0.763

|

图 11 不同进水流速条件下流速区分布 Fig.11 Flow velocity zone division under different inflow velocities |

|

图 12 不同进水流速下养殖增量及流量变化 Fig.12 Increment and flow changes of aquaculture under different inflow velocities |

结合流场和颗粒物排出仿真结果,在本研究中的适宜流速1.1 m/s或者经济适宜流速1.0 m/s时,饵料会在30 s内排出,浪费大量饵料,增加饵料成本和后续水处理难度。若在投饵时采用0.2 m/s的进水流速,饵料排出速度会有效降低,在投饵50 s后饵料留存率依旧可以保持在90%以上,可以保证养殖生物有充分的进食时间。虽然在该流速条件下的适宜流速区小,但短时间的低流速不会过分影响肉质营养和水体交换,不会对鱼体造成伤害,因此,可以在投饵开始时将进水流速调节到0.2 m/s。

养殖生物进食结束后,多余的饵料若不及时排出会产生氨氮和亚硝酸盐等有害物质,对养殖生物造成伤害。在进食结束后,应加快残饵和排泄物的排出。进水流速为1.2 m/s时,20 s左右可以快速排出养殖池内颗粒物,避免养殖池中氨氮和亚硝酸盐的累积。进水流速继续增大可以更快地排出颗粒物,但高流速会直接伤害养殖生物。因此,在养殖生物进食结束后可采用1.2 m/s的进水流速。

3.3 进水流速对养殖池水温调控的影响结合2.3节的仿真结果,计算出0.8、1.1和1.2 m/s的进水流速下将平均水温调节到18 ℃所用的时间和进水流量分别为345 s、48.645 L,276 s、48.576 L,230s、48.760 L。在实际应用中可用15 ℃的入水水温、1.2 m/s的进水流速注水230 s,将22 ℃的池内水温降低到18 ℃。

4 结论本研究使用数值模拟方法,模拟不同进水流速下养殖池内颗粒物排出效率、流场和水温调控的变化。与传统方法相比,本研究提出的循环水养殖进水流速调控方法可以直接获得颗粒物排出量、养殖池内整体水温和流场分布,从而保障养殖安全;可以更低成本确定进水流速调控方案,且在调控时间上精确到秒,确保进水流速调控更精准。在此基础上,以大菱鲆养殖为例提出一套流速调控方法:进食阶段采用0.2 m/s的进水流速,避免饵料快速排出,降低饲料成本;进食结束后,采用1.2 m/s的进水流速持续20 s,可快速排出残饵、避免水质恶化;水温异常时,可采用不同的流速、时间方案来调节养殖池水温。在实际生产中,针对不同生产环境和养殖品种均可参照此方法设计进水流速智能调控方案,降低养殖成本,增加经济效益。

ALMANSA C, REIG L, OCA J. Use of laser scanning to evaluate turbot (Scophthalmus maximus) distribution in raceways with different water velocities. Aquacultural Engineering, 2012, 51: 7-14 DOI:10.1016/j.aquaeng.2012.04.002 |

DE VERDAL H, KOMEN H, QUILLET E, et al. Improving feed efficiency in fish using selective breeding: A review. Reviews in Aquaculture, 2018, 10(4): 833-851 DOI:10.1111/raq.12202 |

DUARTE S, REIG L, MASALÓ I, et al. Influence of tank geometry and flow pattern in fish distribution. Aquacultural Engineering, 2011, 44(2): 48-54 DOI:10.1016/j.aquaeng.2010.12.002 |

FANG C, LI L S, LIANG Z Y, et al. Changes in immune system and growth performance of Litopenaeus vannamei after 40-day challenge with different concentrations of nitrite. Progress in Fishery Sciences, 2022, 43(4): 180-189 [方成, 黎兰诗, 梁震宇, 等. 不同浓度亚硝酸盐亚急性胁迫对凡纳滨对虾生长与免疫功能的影响. 渔业科学进展, 2022, 43(4): 180-189] |

WANG F, LEI J L. Effect of stocking density on growth and quality in muscles of Cynoglossus semilaevis Günther adult fish in industrial recirculating aquaculture. Strategic Study of CAE, 2015, 17(1): 19-26 [王峰, 雷霁霖. 工厂化循环水养殖模式放养密度对半滑舌鳎成鱼生长和肌肉营养成分的影响. 中国工程科学, 2015, 17(1): 19-26 DOI:10.3969/j.issn.1009-1742.2015.01.003] |

GUO L, MA A J, WANG X A, et al. Effects of temperature and salinity on the activities of antioxidant enzymes of juvenile turbot Scophthalmus maximus. Journal of Dalian Ocean University, 2012, 27(5): 422-428 [郭黎, 马爱军, 王新安, 等. 盐度和温度对大菱鲆幼鱼抗氧化酶活性的影响. 大连海洋大学学报, 2012, 27(5): 422-428 DOI:10.3969/j.issn.2095-1388.2012.05.008] |

HU J J, ZHU F, YAO R, et al. Optimization of the inlet pipe layout of circular recirculating water aquaculture tank based on STAR-CCM+. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(21): 244-251 [胡佳俊, 朱放, 姚榕, 等. 基于STAR-CCM+的圆形循环水养殖池进水管布设位置优化. 农业工程学报, 2021, 37(21): 244-251 DOI:10.11975/j.issn.1002-6819.2021.21.028] |

HUANG X X, HEGAZY A M, ZHANG X Z. Swimming exercise as potential measure to improve flesh quality of cultivable fish: A review. Aquaculture Research, 2021, 52(12): 5978-5989 DOI:10.1111/are.15510 |

JONES D R, KICENIUK J W, BAMFORD O S. Evaluation of the swimming performance of several fish species from the Mackenzie River. Journal of the Fisheries Board of Canada, 1974, 31(10): 1641-1647 DOI:10.1139/f74-206 |

LEI J L, MA A J, CHEN C, et al. The present status and sustainable development of turbot (Scophthalmus maximus L.) culture in China. Engineering Science, 2005, 7(5): 30-34 DOI:10.3969/j.issn.1009-1742.2005.05.005 |

LI X, JI L Q, WU L L, et al. Effect of flow velocity on the growth, stress and immune responses of turbot (Scophthalmus maximus) in recirculating aquaculture systems. Fish and Shellfish Immunology, 2019, 86: 1169-1176 DOI:10.1016/j.fsi.2018.12.066 |

LI Y, SUN G X, LIU Y, et al. Effects of temperature on feed intake, growth and digestive enzyme activity of turbot Scophthatmus maximus L. in high stocking density of closed recirculation aquaculture system. Progress in Fishery Sciences, 2011, 32(6): 17-24 [李勇, 孙国祥, 柳阳, 等. 温度对高密度循环海水养殖大菱鲆摄食、生长及消化酶的影响. 渔业科学进展, 2011, 32(6): 17-24 DOI:10.3969/j.issn.1000-7075.2011.06.003] |

LIAO J C. A review of fish swimming mechanics and behaviour in altered flows. Philosophical Transactions of the Royal Society B: Biological Sciences, 2007, 362(1487): 1973-1993 DOI:10.1098/rstb.2007.2082 |

LIU H F, REN X, XUE B R, et al. Systematic optimization of the square arc angle aquaculture tank combining CFD methodology and multi-objective genetic algorithm. Aquacultural Engineering, 2023, 101: 102326 DOI:10.1016/j.aquaeng.2023.102326 |

LÜ Y. Effects of water quality indexes such as ammonia nitrogen on aquaculture a solutions. Northern Chinese Fisheries, 2021, 40(5): 53-56 [吕妍. 氨氮等水质指标对水产养殖的影响及解决办法. 黑龙江水产, 2021, 40(5): 53-56 DOI:10.3969/j.issn.1674-2419.2021.05.015] |

OCA J, MASALO I. Flow pattern in aquaculture circular tanks: Influence of flow rate, water depth, and water inlet and outlet features. Aquacultural Engineering, 2013, 52: 65-72 DOI:10.1016/j.aquaeng.2012.09.002 |

QIAO W, SONG X F, GAO C R, et al. Effects of stocking density on the growth and physiology of adult turbot and changes in water quality. Progress in Fishery Sciences, 2014, 35(5): 76-82 [乔玮, 宋协法, 高淳仁, 等. 养殖密度对循环水系统中大菱鲆(Scophthalmus maximus)生长的影响. 渔业科学进展, 2014, 35(5): 76-82] |

REN X Z, XUE B R, JIANG H Z, et al. Numerical study on the influence of double-inlet pipes system for single-drain rectangular arc angle aquaculture tank on hydrodynamic characteristics. Marine Environmental Science, 2021, 40(1): 50-56 [任效忠, 薛博茹, 姜恒志, 等. 双进水管系统对单通道矩形圆弧角养殖池水动力特性影响的数值研究. 海洋环境科学, 2021, 40(1): 50-56] |

SHEN J Z, SHI M M, RUAN Y J, et al. Effects of variable flow rates on water qualities in recirculating aquaculture system. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(7): 309-314 [沈加正, 史明明, 阮贇杰, 等. 变速流操作调控循环水养殖系统水质效果研究. 农业机械学报, 2016, 47(7): 309-314] |

SIN M G, AN C H, CHA S J, et al. A method for minimizing the zone of low water flow velocity in a bottom center drain circular aquaculture tank. Journal of the World Aquaculture Society, 2021, 52(6): 1221-1233 DOI:10.1111/jwas.12792 |

SUI J Z, TIAN Y C, LI Z Z, et al. Research progress on intelligent feeding technology based on fish feeding behavior. Journal of Tianjin Agricultural University, 2022, 29(2): 63-68 [隋金柱, 田云臣, 李振忠, 等. 基于鱼类摄食行为的智能投饲技术研究进展. 天津农学院学报, 2022, 29(2): 63-68] |

SUN G X, LI Y, TIAN Z, et al. Effects of flow rate on the growth, feed intake and water nitrogen in a closed recirculation aquaculture system of turbots (Scophthatmus maximus L.). Marine Sciences, 2011, 35(5): 53-60 [孙国祥, 李勇, 田喆, 等. 流速对封闭循环水养殖大菱鲆生长、摄食及水质氮素的影响. 海洋科学, 2011, 35(5): 53-60] |

TIAN X L, WANG G D, DONG S L, et al. Effects of salinity and temperature on growth, osmophysiology and energy budget of tongue sole (Cynoglossus semilaevis Günther). Journal of Fishery Sciences of China, 2010, 17(4): 771-782 [田相利, 王国栋, 董双林, 等. 盐度和温度对半滑舌鳎生长, 渗透生理及能量收支的影响. 中国水产科学, 2010, 17(4): 771-782] |

WANG F, LEI J L, GAO C R, et al. Review of industrial recirculating aquaculture research at home and abroad. Journal of Fishery Sciences of China, 2013, 20(5): 1100-1111 [王峰, 雷霁霖, 高淳仁, 等. 国内外工厂化循环水养殖研究进展. 中国水产科学, 2013, 20(5): 1100-1111] |

XU Z, CAO J, QIN X, et al. Toxic effects on bioaccumulation, hematological parameters, oxidative stress, immune responses and tissue structure in fish exposed to ammonia nitrogen: A review. Animals, 2021, 11(11): 3304 DOI:10.3390/ani11113304 |

XUE B R, LI Y F, HU Y X, et al. Numerical simulation on influence of inlet pipe location on the discharge rate of settling solid particles based on computation fluid dynamics. Journal of Dalian Ocean University, 2021, 36(4): 620-628 [薛博茹, 李永锋, 胡艺萱, 等. 基于CFD的进水管布设位置对沉降式固体颗粒排污影响的数值模拟. 大连海洋大学学报, 2021, 36(4): 620-628] |

YANG K, HUANG Z H, MA A J, et al. Transcriptome study of kidney of turbot under high-temperature stress. Progress In Fishery Sciences, 2020, 41(1): 86-95 [杨凯, 黄智慧, 马爱军, 等. 高温胁迫条件下大菱鲆肾脏转录组研究. 渔业科学进展, 2020, 41(1): 86-95] |

YUSOFF F, BANERJEE S, KHATOON H, et al. Biological approaches in management of nitrogenous compounds in aquaculture systems. Dynamic Biochemistry, Process Biotechnology and Molecular Biology, 2011, 5(1): 21-31 |

ZHANG Q, GUI J S, REN X Z, et al. Optimization of flow field in dual-drain square aquaculture tank with relative arc to width ratio. South China Fisheries Science, 2022, 18(4): 119-125 [张倩, 桂劲松, 任效忠, 等. 相对弧宽比对双通道方形养殖池的流场优化研究. 南方水产科学, 2022, 18(4): 119-125] |

ZHANG S H, YU G H, WANG Y, et al. Numerical investigations on temperature and flow field performance of octagonal culture tank under different physical parameters for fish growth based on computational fluid dynamics. Computers and Electronics in Agriculture, 2022, 195: 106821 DOI:10.1016/j.compag.2022.106821 |

ZHONG J X, ZHANG Q, LI X R, et al. Effects of water velocity on the swimming behavior of Anabarilius graham. Chinese Journal of Ecology, 2013, 32(3): 655-660 [钟金鑫, 张倩, 李小荣, 等. 不同流速对鱇(𩷕)白鱼游泳行为的影响. 生态学杂志, 2013, 32(3): 655-660] |