2. 中国海洋大学食品科学与工程学院 山东 青岛 266100;

3. 荣成银海水产有限公司 山东 荣成 264308

2. College of Food Science and Technology, Ocean University of China, Qingdao 266100, China;

3. Rongcheng Yinhai Seafood Co., Ltd., Rongcheng 264308, China

秋刀鱼(Cololabis saira)属颌针鱼亚目(Beloniformes)、竹刀鱼科(Scomberesocidae)、秋刀鱼属(Cololabis),是一种重要的远洋捕捞经济鱼类(王琳等, 2022),因具有较高的营养价值和独特的风味,深受消费者青睐。但由于秋刀鱼具有与海产红肉鱼相似的强烈腥味,限制了其资源的开发和综合利用;目前主要以鲜销和初级加工品为主,而深加工方面主要为秋刀鱼罐头、无骨鱼块等,远远不能满足消费者的需求。

干制作为水产品常见的加工方式之一,不仅可以改善水产品品质,延长水产品的赏味期限;还可赋予干制水产品独特的风味。在水产品加工过程中,脂质等风味前体物质发生水解氧化反应,生成挥发性风味物质,从而表现出独特的气味特征。目前科研人员通常使用气相色谱–离子迁移谱(gas chromatography-ion mobility spectrometry, GC-IMS)、气相色谱–质谱联用技术(gas chromatography-mass spectrometry, GC-MS)结合电子鼻/舌技术,探究样品挥发性物质的微观组成的同时,对样品的宏观风味进行描述,最终将仪器分析与感官评价相结合,系统有效地对样品风味进行综合评价。目前,对干制水产品风味方面的研究逐渐丰富,主要集中在咸干鲅鱼(Scomberomorus niphonius) (简冲等, 2022)、腌腊草鱼(Ctenpharyngodon idellus) (顾赛麒等, 2019)、虾干(Litopenaeus vannamei)(Hu et al, 2021)、风干武昌鱼(Megalobrama amblycephala) (陈方雪等, 2023)等传统干制水产品风味变化的研究,未见关于干制秋刀鱼风味的研究。因此,本研究选用自然干燥、冷风干燥、紫外+冷风干燥3种方式干制秋刀鱼,通过GC-MS和电子舌测定其风味的变化,探究不同干制方式对秋刀鱼风味形成的影响,旨在为秋刀鱼产品风味品质的提升提供理论支持。

1 材料与方法 1.1 实验材料实验用秋刀鱼购于山东蓬莱京鲁渔业有限公司,规格为(100±7) g/尾,2021年9月捕自北太平洋海域,运回实验室后于–50 ℃保存。

1.2 仪器与试剂SNA9-对开门冷风干燥烘箱(江苏宇通干燥工程有限公司);Philips TUV 30 W/G 30 T 8紫外灯(广东省东莞市森夏电子科技有限公司);5975C/7980A型气相色谱–质谱联用仪(美国Agilent公司);75 μm CAR/PDMS/DVB萃取纤维头(美国Supelco公司);TS-5000Z味觉分析系统(日本Insent公司)。

2,4,6-三甲基吡啶、氯化钾和酒石酸均为分析纯,购于国药集团化学试剂公司。

1.3 实验方法 1.3.1 样品制备(1) 将秋刀鱼于4 ℃低温空气解冻,去内脏、划斜刀、洗净后沥干水分。(2)将预处理后的秋刀鱼于(20±2) ℃的室温下置于15%食盐水中浸泡腌制1 h,自然沥干水分。(3)分别进行自然干燥(秋季晴日自然晾晒3 d,环境温度10~20 ℃)、冷风干燥[连续冷风干燥3 d,设置温度为(15±2) ℃]和紫外+冷风干燥[紫外灯照射,冷风连续干燥3 d,设置温度为(15±2) ℃]。

取样点:取步骤(1)的秋刀鱼样品为鲜鱼(CK),步骤(2)的秋刀鱼样品为腌制鱼(0 d),步骤(3)的秋刀鱼样品为自然干制秋刀鱼(N)、冷风干制秋刀鱼(C)和紫外+冷风干制秋刀鱼(U)。每种取3条鱼,去头尾、去骨、去皮后绞碎,置于–20 ℃冷藏备用。

1.3.2 GC-MS测定方法样品前处理:参照Hu等(2021)的方法,取3 g鱼肉样品切碎后放入20 mL顶空瓶中,加入1 μL 2,4,6-三甲基吡啶(TMP, 0.5 mg/mL)作为内标物质,于60 ℃下平衡10 min后,用固相微萃取针萃取30 min,然后于进样口解析5 min。

GC-MS条件:色谱柱为HP-INNOWAX毛细管柱子(30.00 m×0.25 mm×0.25 μm);载气为He,流速1 mL/min,分离比5∶1;进样温度为250 ℃;升温程序为起始温度为40 ℃,保持5 min,以8 ℃/min升至250 ℃,保持5 min。

质谱条件:EI电离源,能量70 eV;离子源温度230 ℃,四极杆温度150 ℃,接口温度250 ℃,扫描范围30~400 m/z。

使用正构烷烃(C6~C30)计算挥发性化合物的线性保留指数,并基于对GC保留指数(RI)和质谱数(MS)与NIST 14和Wiley 11库的比较鉴定挥发性化合物。

使用公式(1)计算各挥发性化合物的含量:

| $ \begin{array}{l}含量(\text{μg}/\text{kg})=\\ \frac{挥发性物质的峰面积}{\text{TMP}的峰面积}\times \frac{0.5\text{μg}(\text{TMP}含量)}{3\text{g}(鱼肉样品量)}\times 1000\end{array} $ | (1) |

使用公式(2)计算气味活性度(odor aroma-active, OAV):

| $ {\text{OA}}{{\text{V}}_i} = \frac{{{{\text{C}}_i}}}{{{\text{O}}{{\text{T}}_i}}} $ | (2) |

式中,Ci为气味物质在样品中的含量,OTi为该气味物质的风味阈值。

1.3.3 电子舌测定方法参照曹荣等(2019)的方法,称取一定质量的鱼肉样品置于料理机中,按照1∶6的比例添加纯净水,匀浆后过滤,取滤液用于TS-5000Z味觉分析系统测试,使用具有广域选择特异性的人工脂膜传感器,传感器介绍见表 1,模拟生物活体的味觉感受机理,实现对5种基本味(酸、涩、苦、咸和鲜)和甜味的评价。每个样品平行分析3次,采用设备自有数据库对数据进行分析。

|

|

表 1 电子舌传感器 Tab.1 E-tongue sensor |

采用GC-MS定量检测不同干制秋刀鱼的挥发性风味物质组成,使用公式(1)计算各挥发性化合物的含量,结果如表 2所示,共检测到包括醛类、醇类、酮类、酸类、烃类以及含氮化合物等58种挥发性风味物质;CK组、0 d组、N组、C组与U组分别检测到28、29、55、53、55种挥发性风味物质,其中以醛类物质的含量最为丰富,这表明干制秋刀鱼风味形成的大部分挥发性化合物是由多不饱和脂肪酸氧化组成的(Fábio et al, 2017)。

|

|

表 2 秋刀鱼的挥发性物质组成 Tab.2 Volatile compounds identified from C. saira |

CK组、0 d组、N组、C组与U组中分别检测到9、11、17、16、17种醛类物质。醛类化合物的阈值较低,如己醛(5 μg/kg)、辛醛(0.59 μg/kg)、壬醛(1.1 μg/kg),通常是传统腌腊肉制品的挥发性成分中含量最高的化合物(唐静等, 2014),能够在脂质氧化过程中快速形成,与其他物质共同增强风味效应,因此,对干制秋刀鱼的风味形成有重要贡献。干制过程中产生了大量C5~C9中等相对分子质量的醛,为秋刀鱼增添了青草香和油脂香气味(Samar et al, 2022; Amjad et al, 2022),其中,丙醛、(反,反)-2,4-庚二烯醛主要来源于亚麻酸氧化,己醛、庚醛、辛醛、反-2-辛烯醛主要来源于亚油酸氧化,辛醛还来源于油酸氧化,同时,油酸氧化还会产生壬醛,丰富秋刀鱼的油脂香气(Fereidoon et al, 2019)。

酮类物质作为脂肪氧化的中间产物,阈值通常比与其同分异构体的醛类物质高,主要起到丰富秋刀鱼气味的作用。2,3-戊二酮和2,3-辛二酮通常呈现奶油味(吴燕燕等,2016),对腥味物质有一定的增强作用,其中2,3-辛二酮在3种干制秋刀鱼中均未检出,说明干制能在一定程度减弱其腥味;而2-壬酮、3,5-辛二烯-2-酮、2-十一酮等具有果香味、花香以及蘑菇味的物质(Amjad et al, 2022)在干制后含量增加,丰富了干制秋刀鱼的整体气味。

在鲜鱼和腌制鱼中均检测到8种醇类,主要以不饱和脂肪醇为主,干制后产生戊醇、壬醇等饱和醇。但1-戊烯-3-醇和1-辛烯-3醇等不饱和醇,是风干鱼中的特征风味物质,其中,1-戊烯-3-醇是由15-脂加氧酶和脂氢过氧化物裂解酶共同催化二十碳五烯酸产生的(唐静等, 2014),具有焦味、肉香味,而1-辛烯-3-醇具有浓郁植物芳香味,使鱼肉具有柔和清香(顾赛麒等, 2019)。

检测到的羧酸主要是己酸和壬酸,游离的羧酸通常是甘油三酯和磷酯的水解产物(Li et al, 2020)。秋刀鱼中含有较多的烃类物质,但烃类物质的阈值较高(李倩等, 2022),对肉制品风味的贡献不大。干制过程中的三甲胺可能是秋刀鱼自身内源酶降解脂质及蛋白质产生(Bekhit et al, 2021),也可能与微生物分解有关(Eman et al, 2016),具有鱼腥味。呋喃类化合物主要源于亚油酸氧化和硫胺素的降解(王朝阳等,2017),干制后的秋刀鱼中含有较多的具有焦香气味的2-乙基呋喃以及具有类火腿香味的反-2-(2-戊烯基)-呋喃(贡慧等, 2017),对干制秋刀鱼的风味也有重要贡献。

根据挥发性物质在秋刀鱼中的含量和阈值,使用公式(2)计算其OAV,进而确定其对干制秋刀鱼整体气味的贡献度;若OAV>1,则该物质对秋刀鱼的风味有重要影响,是气味活性物质(Jiang et al, 2022);若OAV<1,则该物质对秋刀鱼的风味影响较弱,主要起到丰富气味的作用。如表 3所示,己醛、庚醛、顺-4-庚烯醛、辛醛、壬醛、(反,反)-2,4-庚二烯醛、(反,反)-2,6-壬二醛、1-戊烯-3-醇、1-辛烯-3-醇、1-庚醇、2,3-戊二酮、3,5-辛二烯-2-酮和三甲胺是5组秋刀鱼样品共有的气味活性物质,作为秋刀鱼的特征风味化合物表征其油脂味及鱼腥味。反-2-壬烯醛、2-乙基呋喃、反-2-辛烯醛、2-壬酮、2-十一酮、壬醇是3种干制秋刀鱼特有的气味活性物质,其中,具有油脂味(Amjad et al, 2022)的反-2-辛烯醛、壬醇、2-十一酮以及具有焦香味(顾赛麒等, 2019)的2-乙基呋喃在紫外+冷风干制鱼中OAV最高,为紫外+冷风干制鱼带来丰富的油脂香味;此外,顺-2-庚烯醛具有油炸味、烤肉味(Amjad et al, 2022),其在紫外+冷风干制鱼中OAV>1,对于丰富其整体香气也有重要贡献。

|

|

表 3 秋刀鱼挥发性物质的阈值和OAV Tab.3 Odor thresholds and aroma-active compounds of C. saira |

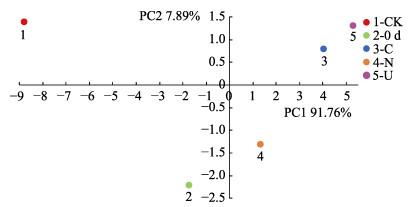

通常使用主成分分析(principal component analysis,PCA)来降低原始数据的维数(Jia et al, 2020),将多个传感器信号转化为几个具有代表性的信息数据进行分析。如图 1所示,主成分累积贡献率为99.65%,可以表征样品的主要滋味信息。CK组与另外几组样品在图中分布明显,这说明新鲜秋刀鱼与其他秋刀鱼样品在味道上差异极大,其中,CK组和0 d组分布于PCA分析图的左侧,N、C、U组分布于右侧,这表明干制后秋刀鱼的整体滋味发生变化,而C组与U组分布较近,说明冷风干制鱼和紫外+冷风干制鱼在滋味上更为接近。

|

图 1 秋刀鱼电子舌主成分分析图 Fig.1 PCA of the E-tongue of C. saira |

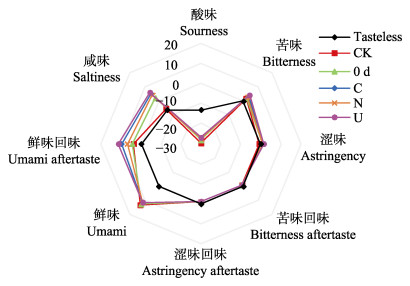

图 2为秋刀鱼的味觉指标雷达图,以参比溶液为基准,5组秋刀鱼样品的酸味、苦味回味和涩味回味均在无味点以下,不具有酸味、苦味回味和涩味回味。而鲜味、咸味和鲜味回味均有较高的响应值,是重要且突出的味觉指标。

|

图 2 秋刀鱼味觉指标雷达图 Fig.2 Radar map of taste indicators of C. saira |

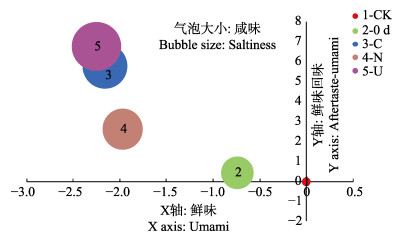

以X轴为鲜味响应值,Y轴为鲜味回味,气泡大小表示咸味,绘制气泡图对比5组样品,结果如图 3所示,干制后的秋刀鱼具有明显的咸味和鲜味回味,鲜味低于鲜鱼,U组的鲜味降低程度与C、N组相近,但其鲜味回味高于C、N组。鲜味回味反映了样品鲜味的持久性和丰富性,与鲜味物质的种类和含量有关,CK、0 d、C、N、U组的鲜味回味依次增大,紫外+冷风干燥产生了较多的鲜味物质,使秋刀鱼的鲜味回味最为强烈,这表明紫外照射在干制秋刀鱼的整体风味提升方面有重要贡献。

|

图 3 秋刀鱼咸味、鲜味和鲜味回味气泡图 Fig.3 Bubble chart of the saltiness, freshness and richness of C. saira |

干制水产品因其具有独特的风味而深受消费者喜爱,在干制过程中脂质极易发生氧化,脂质降解通常会产生脂肪族醛、酮、醇、酸、酯等,从而产生特有的肉类香气(Amjad et al, 2022)。

热、光、光敏剂、氧等可以催化脂质氧化和风味活性成分的形成(Lilian et al, 2017)。基态的分子氧处于其三重态(3O2),使不饱和脂肪酸自氧化形成氢过氧化物,氢过氧化物极不稳定,分解为许多具有气味活性的挥发性二级脂质氧化产物,如酮、醛、烃、醇等。紫外光或肌红蛋白等使氧分子激发为单线态氧(1O2)(Celia et al, 2021),使脂质发生光氧化。1O2比3O2更亲电,因此具有强烈的反应性,导致光氧化时脂肪酸的反应速率比自氧化时更快。酶氧化通过脂肪氧合酶立体选择性的催化含有1,4-顺,顺戊二烯基团的多不饱和脂肪酸发生不可逆氧化,并产生立体特异性的共轭二烯脂肪酸氢过氧化物,裂解生成醇、醛、酮等小分子化合物,对食品风味形成有重要贡献(王帮国等, 2018)。自然干制秋刀鱼发生光氧化、自氧化、酶氧化共同促进(反,反)-2,4-庚二烯醛、2,3-戊二酮等挥发性化合物大量积累。冷风干燥过程中,冷风循环一定程度延缓了光氧化和酶氧化,使脂质氧化生成的风味物质减少,导致冷风干制秋刀鱼风味较为平淡。紫外+冷风干燥加工过程中,紫外照射在一定程度上促进了光氧化,使得挥发性化合物的种类和含量均增加,尤其是积累了大量的顺-4-庚烯醛、辛醛、顺-2-庚烯醛和2-乙基呋喃等物质,丰富了干制秋刀鱼的油脂香味。

此外,干制过程中秋刀鱼的脂质氧化产物还参与以Strecker降解为主的非酶褐变反应,如脂质氧化产物(E)-2-(E)-4-烯醛与赖氨酸反应生成2-甲基-2-戊烯醛(尤海琳等, 2019),对其风味有重要影响,C、N、U组2-甲基-2-戊烯醛的含量分别为187.86、296.94和481.81 μg/kg,因而,推测3种干制加工中紫外+冷风干燥组的秋刀鱼脂质氧化及Strecker降解程度相对较高。

使用电子舌模拟人类味觉,通过检测各种味物质和人工脂膜之间的静电作用或疏水性相互作用产生的膜电势的变化(Lu et al, 2022),准确、客观地对干制秋刀鱼进行酸味、涩味、苦味、咸味、鲜味、甜味及回味评价。食盐腌制有利于增咸提香,鲜味回味可能与干制过程中组氨酸的积累有关(翁世兵等, 2007),使其风味更加浓厚。3种干制方式均能使秋刀鱼咸味和鲜味回味显著增加,而紫外+冷风干制鱼咸味和鲜味回味变化显著,具备较为丰富的滋味和回味。

4 结论干制后秋刀鱼的挥发性气味发生明显变化,自然干燥、冷风干燥和紫外+冷风干燥3种干制方式均不同程度地增加了秋刀鱼的油脂香味而丰富其香味,其中,紫外+冷风干燥过程中产生了较多的具有油脂香味的物质,同时,顺-2-庚烯醛和2-乙基呋喃等物质的增加丰富了干制秋刀鱼的气味。咸味、鲜味和鲜味回味是干制秋刀鱼重要的味觉指标,3种干制方式均增加了秋刀鱼的咸味和鲜味回味,尤其紫外+冷风干燥极大地丰富了其滋味和回味。综上,上述3种干制方式中,紫外+冷风干制加工能够最大程度地丰富秋刀鱼的风味。

AMJAD S, SAM A, WANG J, et al. Aroma compounds identified in cooked meat: A review. Food Research International, 2022, 157: 111385 DOI:10.1016/j.foodres.2022.111385 |

BEKHIT A, GITERU S, HOLMAN B, et al. Total volatile basic nitrogen and trimethylamine in muscle foods: Potential formation pathways and effects on human health. Comprehensive Reviews in Food Science and Food Safety, 2021, 20(4): 3620-3666 DOI:10.1111/1541-4337.12764 |

CAO R, ZHAO L, WANG L Z, et al. Taste characteristic analysis of Porphyra yezoensis during different harvest periods: A study based on electronic tongue technology. Progress in Fishery Sciences, 2019, 40(1): 147-154 [曹荣, 赵玲, 王联珠, 等. 基于电子舌技术分析不同采收期紫菜的滋味特征. 渔业科学进展, 2019, 40(1): 147-154] |

CELIA A, JOSE M, FRANCISCO J P, et al. The chemistry of reactive oxygen species (ROS) revisited: Outlining their role in biological macromolecules (DNA, lipids and proteins) and induced pathologies. International Journal of Molecular Sciences, 2021, 22(9): 4642 DOI:10.3390/ijms22094642 |

CHEN F X, DENG Y, CHEN L W, et al. Quality change and aroma formation of pre-cooled air-dried Wuchang fish during drying. Modern Food Science and Technology, 2023(2): 9-17 [陈方雪, 邓祎, 谌玲薇, 等. 预制冷风风干武昌鱼干制过程中的品质变化及香气形成. 现代食品科技, 2023(2): 9-17] |

EMAN S H, AL-SABAGH. Effect of freezing and frozen storage on amino acid profile and fatty acid pattern in imported and local meat. Alexandria Journal for Veterinary Sciences, 2016, 49(1): 113-121 DOI:10.5455/ajvs.209080 |

FÁBIO A, VALQUÍRIA C, MARTA S, et al. Aroma profile and consumer liking of salted and dried chicken meat: Effects of desalting and cooking methods. International Journal of Food Properties, 2017, 20(12): 2954-2965 DOI:10.1080/10942912.2016.1263653 |

FEREIDOON S, ABREHEM A. Lipid-derived flavours and off-flavours in food. Encyclopedia of Food Chemistry, 2019, 182-192 |

GONG H, YANG Z, LIU M, et al. Changes in volatile flavor compounds during heat processing of Cololabis saira. Meat Research, 2017, 31(1): 25-31 [贡慧, 杨震, 刘梦, 等. 秋刀鱼热加工后挥发性风味成分变化的分析. 肉类研究, 2017, 31(1): 25-31] |

GU S Q, TANG J J, ZHOU X X, et al. Quality change and aroma formation in cured fish during traditional sun drying processing. Food Science, 2019, 40(17): 36-44 [顾赛麒, 唐锦晶, 周绪霞, 等. 腌腊鱼传统日晒干制过程中品质变化与香气形成. 食品科学, 2019, 40(17): 36-44] |

HU M, WANG S, LIU Q, et al. Flavor profile of dried shrimp at different processing stages. LWT-Food Science and Technology, 2021, 146: 111403 DOI:10.1016/j.lwt.2021.111403 |

JIA Z, SHI C, WANG Y, et al. Nondestructive determination of salmon fillet freshness during storage at different temperatures by electronic nose system combined with radial basis function neural networks. International Journal of Food Science and Technology, 2020, 55(5): 2080-2091 DOI:10.1111/ijfs.14451 |

JIAN C, WANG L Z, WANG S Y, et al. Changes in flavor substances of traditional dried-salted Spanish mackerel during natural air-drying process. Chinese Fishery Quality and Standards, 2022, 12(1): 22-28 [简冲, 王灵昭, 王善宇, 等. 传统咸干鲅鱼自然风干过程风味物质变化. 中国渔业质量与标准, 2022, 12(1): 22-28] |

JIANG H, ZHANG M, YE J, et al. HS-SPME-GC-MS and OAV analyses of characteristic volatile flavour compounds in salt-baked drumstick. LWT, 2022, 170: 114041 |

LI F, FENG X, ZHANG D, et al. Physical properties, compositions and volatile profiles of Chinese dry-cured hams from different regions. Journal of Food Measurement and Characterization, 2020, 14: 492-504 |

LI Q, XIA G L, CAO R, et al. Changes in the flavor of Apostichopus japonicus gonads during enzymatic hydrolysis. Progress in Fishery Sciences, 2022, 43(6): 239-248 [李倩, 夏光丽, 曹荣, 等. 仿刺参性腺酶解过程风味变化. 渔业科学进展, 2022, 43(6): 239-248] |

LILIAN R B M, NEURA B. Influence of salt on lipid oxidation in meat and seafood products: A review. Food Research International, 2017, 94: 90-100 |

LU L, HU Z, HU X, et al. Electronic tongue and electronic nose for food quality and safety. Food Research International, 2022, 162(Part B): 112214 |

SAMAR M B, CLARICE N, MOHAMED A. Dissecting grilled red and white meat flavor: Its characteristics, production mechanisms, influencing factors and chemical hazards. Food Chemistry, 2022, 371: 131139 |

TANG J, ZHANG Y Y, WU H Z, et al. Recent progress on volatile flavor compounds of traditional Chinese cured meat products. Food Science, 2014, 35(15): 283-288 [唐静, 张迎阳, 吴海舟, 等. 传统腌腊肉制品挥发性风味物质的研究进展. 食品科学, 2014, 35(15): 283-288] |

WANG B G, YU Z Y, LIN L, et al. Effect of ultrasonic wave and ultra high pressure treatment on conformation and enzyme activity of lipoxygenase in silver carp muscle. Food Science, 2018, 39(3): 169-175 [王帮国, 余振宇, 林琳, 等. 超声波、超高压对白鲢鱼肌肉脂肪氧合酶构象及酶活力的影响. 食品科学, 2018, 39(3): 169-175] |

WANG L, ZHAO L, QI X M, et al. Nutritional composition analysis and quality evaluation of muscles of different specifications of Cololabis saira. Journal of Food Safety and Quality, 2022, 13(21): 6815-6820 [王琳, 赵玲, 齐祥明, 等. 不同规格秋刀鱼肌肉的营养成分分析与品质评价. 食品安全质量检测学报, 2022, 13(21): 6815-6820] |

WANG Z Y, WANG Z Z, LI Y, et al. Research on the detection of the volatile substances changes of canned oil skipjack during storage. Science and Technology of Food Industry, 2017, 38(8): 316-321 [王朝阳, 王祖忠, 李晔, 等. 油浸鲣鱼罐头贮藏过程中挥发性成分的变化规律研究. 食品工业科技, 2017, 38(8): 316-321] |

WENG S B, SUN H L. Marine umami substances and characteristic tastes of seafood. China Condiment, 2007(11): 21-27 [翁世兵, 孙恢礼. 海产鲜味物质及海产品特征滋味的研究进展. 中国调味品, 2007(11): 21-27] |

WU Y Y, WANG Y Q, LI L H, et al. Analysis of volatile components in various cured hairtail byelectronic nose and HS-SPME-GC-MS. Journal of Fisheries of China, 2016, 40(12): 1931-1940 [吴燕燕, 王悦齐, 李来好, 等. 基于电子鼻与HS-SPME-GC-MS技术分析不同处理方式腌干带鱼挥发性风味成分. 水产学报, 2016, 40(12): 1931-1940] |

YOU H L, JIANG L, LIU K K, et al. Effect of marine phospholipid oxidation on food flavors. Food and Fermentation Industries, 2019, 45(11): 268-273 [尤海琳, 姜璐, 刘锴锴, 等. 海洋磷脂氧化及其对食品风味的影响. 食品与发酵工业, 2019, 45(11): 268-273] |